CATAPHORESIS FACILITY

The Cataphoresis (KTL) process operates with 15 immersion baths and two robotic systems. The dimensions of the bar (basket) on which the parts are suspended are: width 90 cm, depth 170 cm, height 180 cm. The bath size is 2 m³, and the electrophoresis bath has a volume of 15 m³. The production capacity is 25 bars/shift (12,870,000 kg/year).

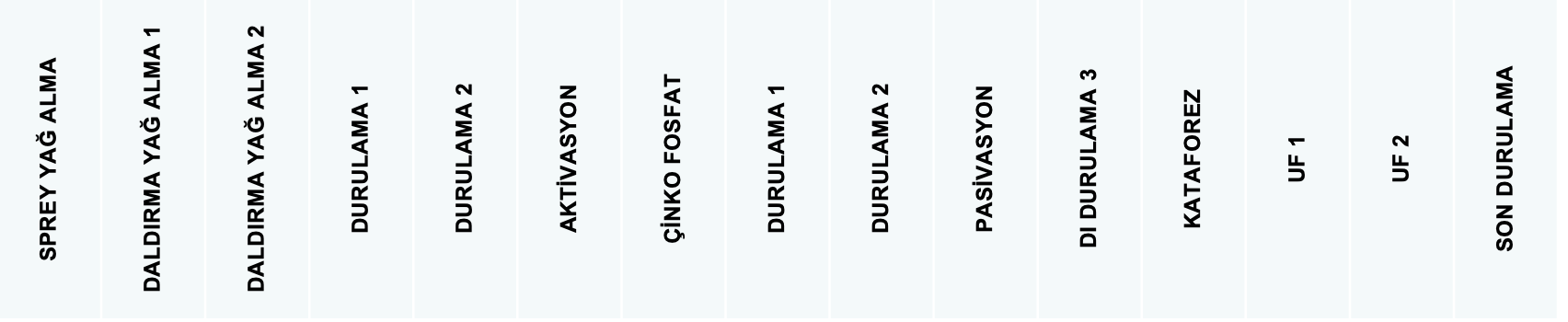

Cataphoresis coating is carried out through a flow including incoming quality control (IQC), suspension, coating process, baking (box type), final quality control (FQC), packaging, and shipment to the warehouse.

In our laboratory, relevant tests (gloss, dry film thickness, salt spray, corrosion cycle, pencil hardness, impact and adhesion resistance, persose hardness, flexibility, water immersion, moisture resistance, and cycling tests) are performed within the scope of our certified quality management systems and customer requirements.